General Description

Excellent Filling Effect: pneumatic filling with a dedicated filling device, including nozzle, conveying pipe, and non-return valve, which has high filling precision that can be controlled between 0.1% – 1%.

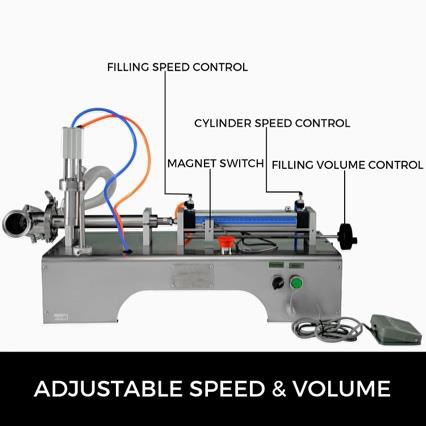

Arbitrarily controllable process: the entire filling process can be arbitrarily controlled, including the operating speed of the air cylinder, filling speed, and filling volume, to meet different needs.

Stainless Steel Construction: pneumatic filling machine made from 304 stainless steel materials, resistant to corrosion, rust, acid, and alkali. (Easy and safe to operate)

Advanced Air Pressure Gauge: Adaptable air pressure gauge to accurately monitor air pressure change. Two models are available for operating the machine; you can choose automatic operation or pedal control.

Various Applications: Widely used in pharmaceutical products, cosmetics, food, pesticides, and special industries (suitable for low-density fluid filling). This product needs to work with an air compressor (not offered).

Features

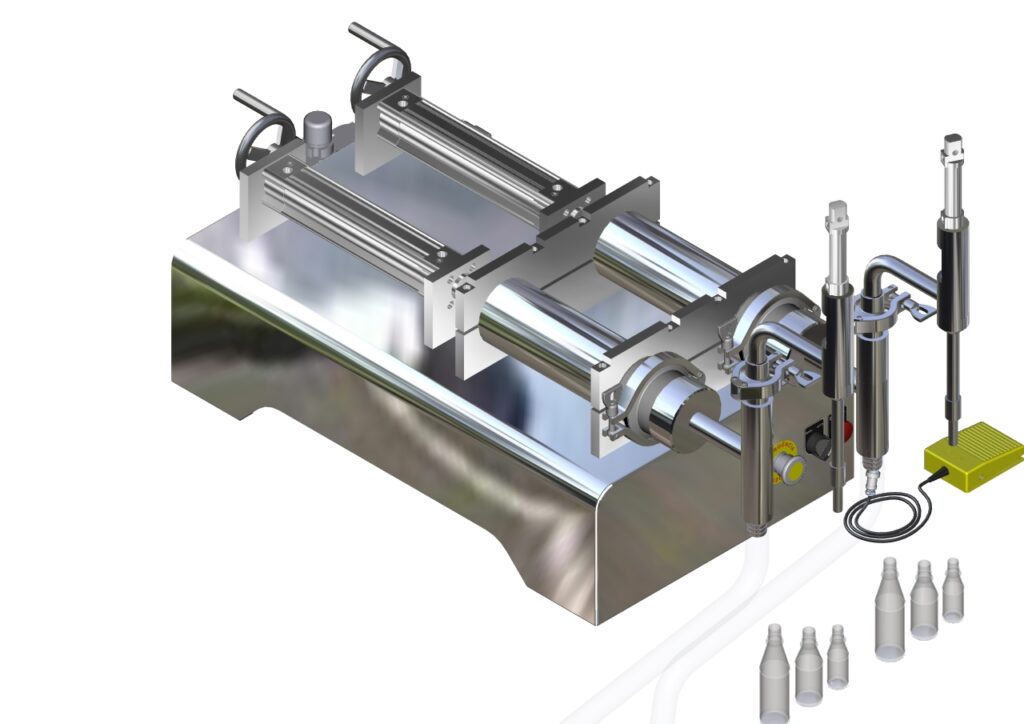

- Nozzle Manual Filling machine with a production capacity of 20 – 40 cup/min.

- Ability to use different viscosity levels and weights accordingly to customer’s desires.

- Weight range is 100cc-1000cc

- Suitable for liquid and semi-liquid filling that does not have high level of heat.

- Manual and semi-automatic operating options; if the operator wants to change to manual mode, the filling process can be filled semi-automatically by adjusting the tine via the pedal connected to the machine.

- Easy-to-use nature with the ability to make various mechanical adjustments, the nozzle is also adjustable.

- Quick and easy assembly and disassembly process (easy to clean).

- Emergency button available (emergency button can be disabled).

- The machine is equipped with a system that doesn’t allow the nozzle to drip, this way, the filled package doesn’t drip, and the filling weight also eliminates the possibility of a fire.

- The machine is equipped with a system that doesn’t allow the nozzle to drip, this way, the filled package doesn’t drip, and the filling weight also eliminates the possibility of a fire.

- The machine body that is in contact with the product is made from stainless steel (AISI 304), if necessary, steel and plastic are used in some parts.

- Different nozzle types are available according to the product.

- Grammage precision is ±1%

- Works with pneumatic air (6 bar).

Usage

You can fill all liquids related to cosmetics, chemical substances, food industry (honey, molasses, pomegranate syrup, jam, tahini, creams, fruit juice, olive oil, etc.), medicine, and cleaning sector (shampoo, mineral oil, liquid soap, softener, cologne, antibacterial gel, etc.)

High viscosity Products Filling Machine

Low viscosity Products Filling Machine

For inquiry and more information

Please contact us on

Sales@termocup.com

https://www.facebook.com/termocupfillingmachine

https://www.linkedin.com/in/termocup-machine